Achieve optimal results by calculating your required machine power

Calculating machine power using the relatively simple K factor method increases efficiency, optimizes power consumption, reduces operating costs, and improves productivity.

In some shops, a single machine or an entire machining cell is dedicated to manufacturing a specific component type using a certain material. In this case, it is important to understand material K factors, which are constants assigned to different material groups that are used to calculate the maximum material removal rates (MRR) based on a machine’s power.

While the American Iron and Steel Institute (AISI) machinability rating is a good baseline of how difficult some materials are to machine, it does not provide quantifiable data on how to approach a material from a machine tool requirement standpoint. Even though many advancements have been made to cutting tools, CAM software, and machine tools, certain parts and machine setups can still benefit from traditional heavy roughing methods.

Machine Productivity

Many machinists often find themselves in a situation where their tool, which can perform at a certain MRR level, is limited by the machine’s power. For job shops or manufacturers with smaller lot sizes and multiple different materials/parts, this may not pose a productivity issue, but it does require careful attention during programming and tool selection. For manufacturers that produce large quantities of a single part, machine power is crucial when choosing what sort of machine tools to invest in.

To determine the horsepower requirements, cutting parameters must first be selected. In the case of larger tools and heavy cuts, a large amount of power will be required from the machine. This is where we can begin to make calculations, and step No. 1 is determining the MRR of the cutter.

In milling, MRR is the amount of material removed stated in cubic inches per minute (IPM). The calculation is simple:

MRR = DOC x width of cut x IPM

MRR is a great way to quantify machine productivity because higher cubic removal rates equal lower cycle times. When a machinist understands the capability of the cutters they are using, they often begin to look for higher-powered machines to increase their MRR. To determine what sort of power is required, calculations are made using the K factor.

The K Factor

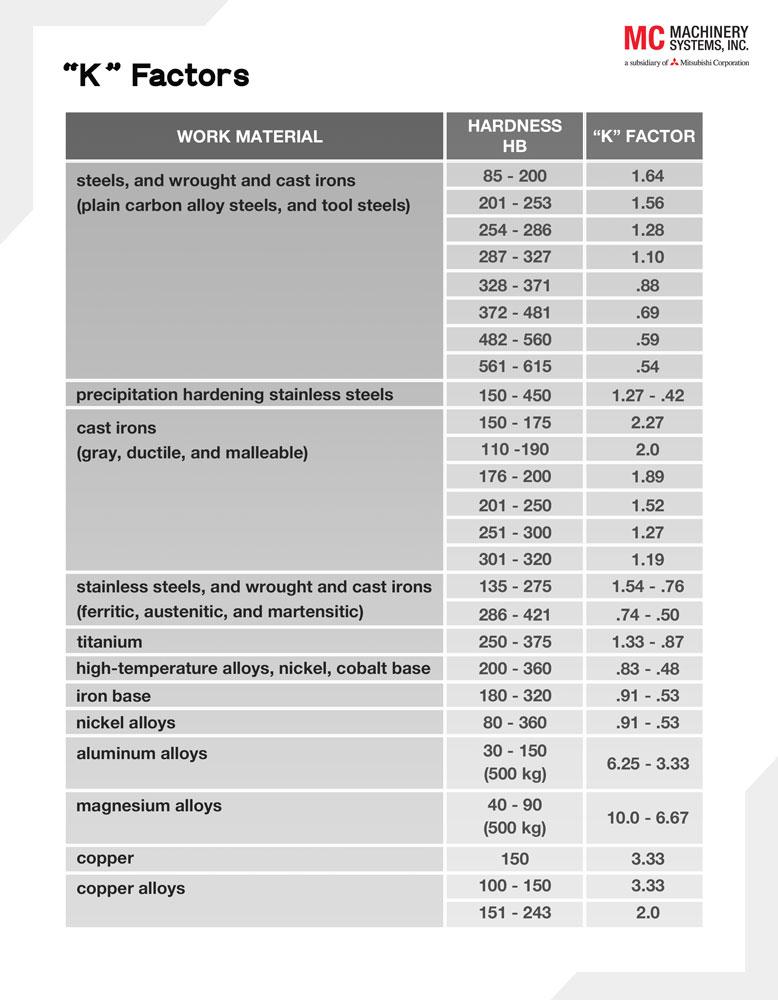

Just like materials are given machinability ratings, there is another constant called the K factor that often is assigned to different material groups. A material’s K factor represents the MMR that can be achieved by 1 HP. These K factors are one way of determining the horsepower required by a machine tool for a specific job.

We use K factors in a formula to determine the required horsepower of the machine (HPm) based on the cutter’s MRR, K factor, and spindle efficiency (E), which typically is around 80 per cent. The formula is: HPm = (MRR/K)/E.

Machine Requirement Example

- Width of cut: 2 in.

- DOC: 0.12 in.

- 27 IPM

- Material: 4140 alloy steel, 230 HB (Brinell hardness), 1.56 K factor

To achieve an MRR of 6.48 cubic IPM using these parameters, the machine requires around 5.2 HP. This knowledge can be very handy to determine if the programmed tool and parameters can handle the job. Similarly, if you are looking to invest in a machine strictly for roughing a certain material, you can determine your power requirements to achieve maximum MRR.

Of course, there are limitations to this calculation.

The cutting tool’s sharpness and distribution of cutting forces affect the amount of power required. Factors, such as setup rigidity, may require that parameter adjustments be made. K factors also are approximated based on hardness and type and apply to material types in general, not specific SAE/AISI numbers.

Of course, there are other methods of calculating power that require a much more in-depth understanding of a cutting tool’s geometry, the workpiece material properties, and even tool wear.

But for a quick and easy approximation, the K factor method is very useful for determining machine power—and it can deliver a substantial payoff.

By using simple calculations, machinists can predetermine their required milling horsepower to avoid downtime and the possibility of having increased cycle times caused by an underpowered machine. Many ways exist to work around a lack of power, including high-speed milling methods and alternate machining technologies, but by approximating your required power you can increase MRR and, therefore, machining productivity.

Adam Dimitroff is regional sales representative for MC Machinery Systems Canada, 50 Vogell Rd., Unit #1, Richmond Hill, Ont. L4B 3K6, 905-737-1265, www.mcmachinery.com.

Article From: